Sheet metal and welding work

Do you need help with sheet metal or welding work?

When it comes to welding and sheet metal work, we’re happy to assist — focusing on your requirements, processes and products.

At Verkstadsbolaget — a mechanical engineering workshop — you’ll find many years of experience in welding most materials, delivering high-quality products. We strive for close and transparent collaboration with you to ensure a solid and reliable result.

Welcome to us!

Get in touch with us

You’re welcome to get in touch with us — we’re here to help.

Henrik Lindblom

Workshop Manager

Phone. +46 533-69 14 88

Mob. +46 70-277 02 92

Email Henrik

Welding & sheet metal work

We can help you with:

- MIG welding

- MAG welding

- MMA welding (stick welding)

- TIG welding

- Laser cutting – single pieces and high volumes

- Bending – single pieces and high volumes

- Press braking

- Rolling

- Punch pressing

- Tumbling

- Surface treatment

- Traceability

- 3D CAD/CAM integration

- Text and ID marking

Services

Welding methods

We can help you with MIG welding, MAG welding, MMA welding (stick) and TIG welding.

We handle most materials and weld in black steel, stainless steel and aluminium.

Verkstadsbolaget holds licences for most methods and materials in our mechanical workshop, and we can adapt this to your needs and requirements.

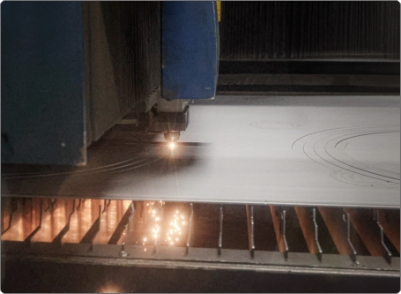

Laser cutting

If you need help with laser cutting, we’re happy to assist — we handle both single-piece production and high-volume runs. Our laser can process sheets up to 1500 mm in width and 3000 mm in length, with thicknesses up to 20 mm in black steel, 12 mm in stainless steel and 8 mm in aluminium.

The machine is equipped with a paternoster system, allowing for unmanned operation at higher volumes.

Do you have any questions about our capacity?

Bending

If you need help with sheet metal bending, we’re happy to assist — Verkstadsbolaget handles both single-piece production and high-volume runs. Our press brake can bend sheet metal up to 3000 mm in length, with thicknesses up to 15 mm depending on length, material and radius.

Some customers have also had us bend plexiglass — feel free to let us know what you need, and we’ll do what we can to help you.

Machine park

To produce your products, we operate a modern and flexible mechanical workshop. In machining, we have several CNC-controlled and manual machines, as well as a bar feeder and a pallet machine. In addition to machining, we also have a sheet metal department with laser cutting, bending and welding, capable of handling most materials and methods.

If needed, we can also tumble your products. This flexibility allows us to manufacture complex components within our workshop without having to send them between multiple companies.

Download

machine list

Other services

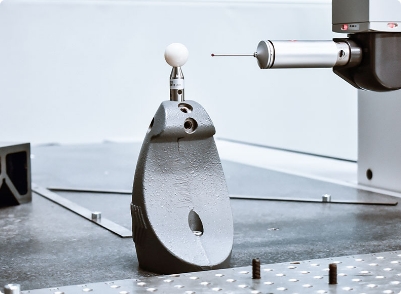

Coordinate measurement

If you need help with coordinate measurement, we’re happy to assist using our coordinate measuring machine. Verkstadsbolaget uses a Hexagon machine capable of measuring products up to 2000 mm in length, 900 mm in width and 800 mm in height, with a maximum weight of 2 tonnes. Measurement reports can be delivered in various formats such as PDF or Excel, depending on customer requirements — most commonly Excel.

Surface treatment

If you need your products surface treated, we can help. Verkstadsbolaget has strong local partners who handle galvanizing, nickel plating, powder coating and wet painting according to your requirements.

Traceability

If you require traceability to the raw material via charge numbers or certificates, we are experienced in handling this in our production and in our ERP system, Monitor.

Engineering

We can receive 3D files for CNC preparation and programming, enabling a fast transition from drawing to finished part.

If possible, please send the files to us in STEP or IGES.

If you need engineering support, we’re happy to help. Verkstadsbolaget values close collaboration to develop solutions that make your work easier.

All products are CE marked before delivery, and we also perform a load test to ensure that the lifting equipment withstands the loads it is designed for. If we lack the weights or capacity required for this test, we work with partners who assist us.

This enables us to manufacture lifting tools with high lifting capacity — feel free to ask us where the limits are.